Reduced errors, increased inspection rates

An automated visual inspection system can do more work at a higher rate of efficiency than its human counterparts. Automated inspection systems with machine vision can achieve 100% inspection of parts, while even the most skilled human inspectors can hope for about 80% at best. More distinct parts, and the minute details of those parts, can be analyzed at lightning speed.

100% compliance rates

Correct labeling is significant for certain products, particularly in the pharmaceutical industry. Adopting AVI can ensure that all labels are accurate and applied in the proper location, eliminating the worry that comes with accidental noncompliance to pharmaceutical product standards.

Improved processes

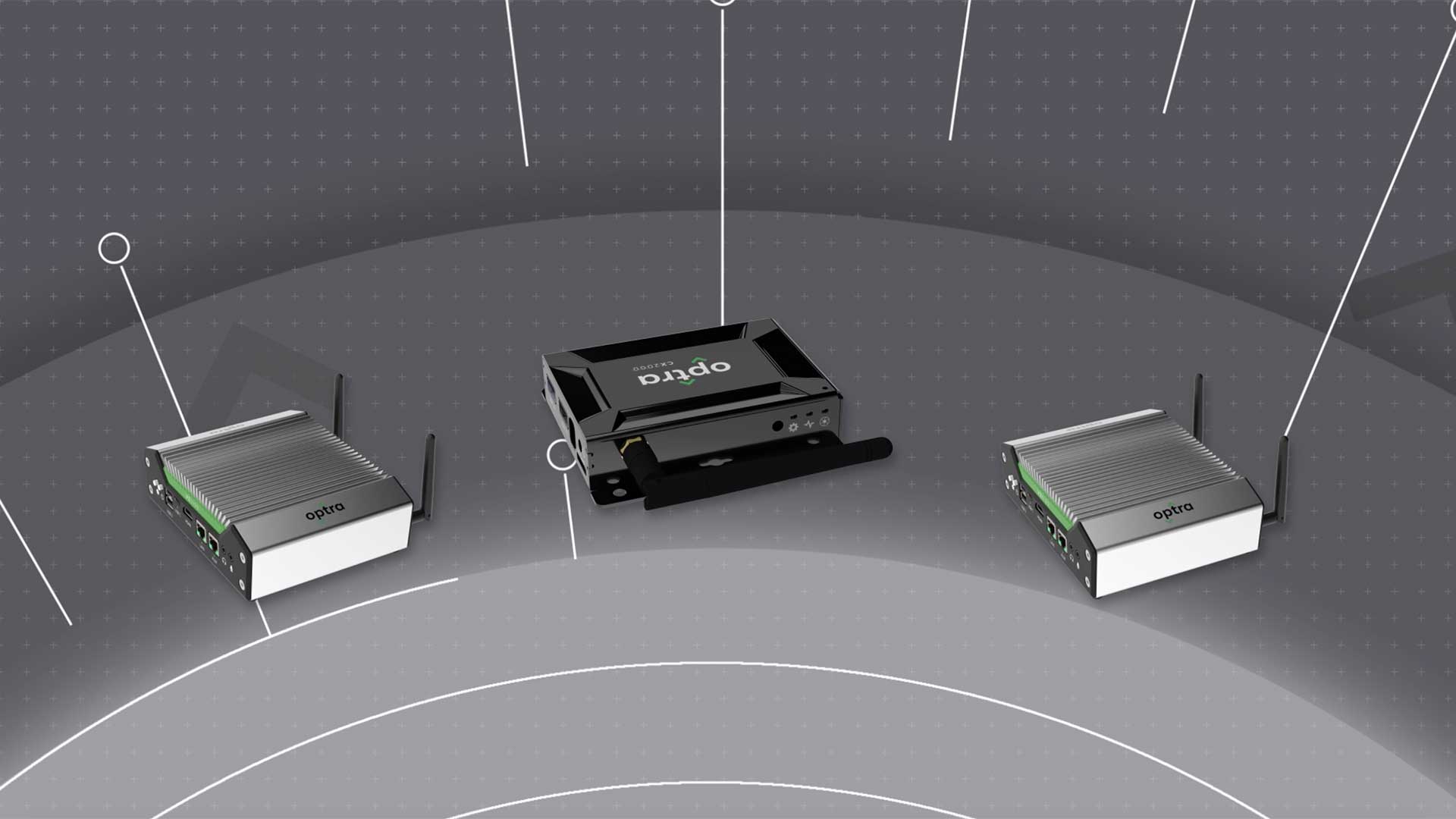

Optra’s automated system gathers consistent data and is a tremendous asset for finding flaws and vulnerabilities in your manufacturing process. The more data a visual inspection system consumes thanks to machine learning and neural networks, the better it understands desirable outcomes. Whether it be obstructions in assembly, warehousing, or any other department, errors and waste apparent to AVI can help manufacturers locate problems in their processes and adjust resources accordingly.

Reduced costs

Besides driving efficiency in quality control, an automated visual inspection can lower costs by reducing the need to hire dedicated product inspectors. Using AVI as part of the manufacturing process almost completely eliminates the potential cost of additional production runs to correct defective parts.